- Skid-Mounted Pilot Plant Design & Engineering for Confident Scale-Up

Turnkey Pilot Plants

Turnkey Pilot Plants

Pilot plants are the critical bridge between laboratory research and full-scale commercial production. At Sherle, we specialize in the turnkey design, engineering, and supply of skid-mounted pilot plants that help organizations validate new technologies, reduce scale-up risk, and move confidently toward commercialization.

Our pilot plants support:

- Startups proving first-of-a-kind processes

- SMEs expanding into new chemistries or products

- Established companies testing new routes, catalysts, or configurations

By combining strong process understanding with disciplined engineering, we deliver pilot plants that are safe, flexible, scalable, and built for real operating conditions – not just experimentation.

We serve clients across chemical, petrochemical, oil & gas, bio-refinery, pharmaceutical, polymer, and specialty chemical industries.

Why Pilot Plants Matter

Laboratory data alone is rarely sufficient to predict real-world plant behavior.

A well-designed pilot plant allows you to:

- Understand true process operability

- Identify heat- and mass-transfer limitations

- Expose hidden bottlenecks and control issues

- Evaluate safety behavior under dynamic conditions

- Generate reliable data for commercial BEP and Detailed Engineering

For startups and technology developers, pilot plants also provide credible proof-of-concept for investors, licensors, and regulatory discussions.

Most importantly, pilot plant data becomes the engineering backbone for commercial design – significantly reducing surprises during scale-up.

Every pilot plant we design is engineered with future scale-up in mind.

Our skid-mounted systems are:

- Modular and compact, can be made containerized for ultralow footprint

- Flexible for future modifications

- Automated using PLC/DCS

- Designed to recognized ASME, API, IEC, and ISA practices

- Cost-effective without compromising safety or reliability

These are not one-time experimental rigs – they are serious engineering assets that evolve with your process.

How Sherle Pilot Plants Are Different

World-Class Components & Equipment Integration

Pilot plant reliability depends heavily on component selection. At Sherle, we partner exclusively with globally recognized OEMs to ensure precision, safety, and long-term operability.

We routinely integrate industry-leading equipment such as:

- Micro-metering pumps from LEWA, Eldex, Pulsafeeder, and Haskel for accurate low-flow dosing

- Slurry pumps from Netzsch and Egger for solids-handling services

- Compressors from Mehrer, Fluitron, Atlas Copco, and Sundyne for high-pressure and specialty gas duties

- Flow measurement technologies including Coriolis, vortex, magnetic, thermal mass, and rotameters

- High-pressure valves and fittings from Swagelok, Autoclave Engineers, Maximator, and Neles

- Control valves from Badger Meter, Fisher, Flowserve, and Samson

- Safety devices such as PSVs and rupture discs from LESER, BS&B, Fike, Swagelok, and Hoke

- Heating systems including electric furnaces and line/jacket tracing from Applied Test Systems, Horst, HTS Amptek, and Sensewell

This component philosophy ensures that pilot plants meet the performance expectations of R&D teams, startups, EPC contractors, and global corporations alike.

Sherle follows a structured, globally accepted engineering workflow to ensure predictable, high-quality delivery of pilot plants.

Our typical execution path includes:

- Basic Engineering Package (BEP)

- Detailed Engineering Design (DED)

- Modular Skid Engineering & Fabrication

- Factory Acceptance Testing (FAT)

- Site Acceptance Testing (SAT), commissioning, and operator training

This disciplined approach minimizes technical risk, avoids late-stage changes, and accelerates commissioning.

Our Design & Delivery Workflow

Basic Engineering Package (BEP)

During BEP, we convert process concepts, lab data, or simulation results into a structured and scalable engineering design.

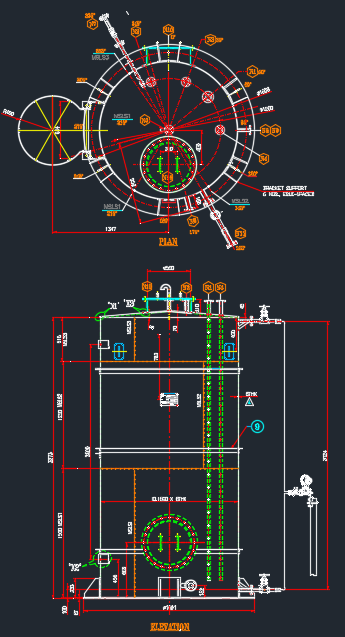

BEP activities include development of the design basis, preparation of PFDs and P&IDs, heat and mass balance development, control narratives, preliminary equipment sizing and datasheets, and preparation of equipment GA drawings and layout concepts. We also perform process and utility line sizing, hydraulic calculations, and prepare Bills of Materials.

Electrical and control deliverables at this stage include Electrical Bills of Material (EBOM), detailed I/O lists and mapping, control system architecture, and preliminary single-line diagrams.

Detailed Engineering transforms the approved BEP into construction-ready documentation.

Process engineering deliverables include final IFC P&IDs, final heat and mass balances, finalized equipment datasheets, detailed equipment design calculations, final hydraulic analysis, and relief system design.

Piping engineering covers piping material specifications, fabrication-ready isometric drawings, optional 3D models with clash checks, pipe support documentation, and finalized valve datasheets.

Mechanical engineering includes final mechanical datasheets, fabrication drawings for vessels and equipment, general arrangement drawings, and mechanical design calculations compliant with ASME and API codes.

Electrical and control engineering deliverables include final electrical load lists, IFC single-line diagrams, cable schedules, detailed panel GA drawings, final instrument index and I/O lists, loop diagrams, control narratives, cause-and-effect matrices, and hook-up drawings.

Detailed Engineering Design (DED)

Modular Skid Design & Fabrication

Pilot plants are engineered as compact, transportable skids to simplify fabrication, transportation, and installation.

Skids are fabricated using powder-coated mild steel, aluminum, or hybrid structures, depending on service requirements. Process and utility lines are constructed using SS316/316L tubing or lined SS/MS/CS piping, with layouts optimized for safety, accessibility, and future modification.

Factory Acceptance Testing (FAT)

Before shipment, each pilot plant undergoes comprehensive FAT at our facility. Instrumentation, control logic, safety interlocks, and system functionality are verified to ensure readiness for site installation.

Site Acceptance Testing (SAT) & Commissioning

Through Sherle and trusted execution partners, we support on-site installation, commissioning, startup assistance, and operator training. This ensures a smooth transition from fabrication to operation and allows early troubleshooting under controlled conditions.

Sherle delivers turnkey pilot plants for a wide range of applications, including:

- Fixed-bed catalyst evaluation units

- Bio-refinery pilot plants

- Petrochemical and polymerization pilot systems

- Synthetic fuels demonstration units

- High-pressure, high-temperature fixed-bed reactors

- Pharmaceutical pilot-scale systems

- Chemical dosing and metering skids

- High-pressure, high-temperature stirred reactor units

Each pilot plant is designed for precision, flexibility, and scalability, enabling clients to generate reliable data and move confidently toward commercial deployment.

Applications of Our Pilot Plants

Why Sherle for Pilot Plant Engineering?

We understand that pilot plants are not just experimental units—they are critical decision-making tools. Our strength lies in combining process insight, scale-up experience, and disciplined engineering execution to deliver pilot plants that truly support commercialization.

Whether you are a startup proving your technology or an established company testing the next generation of processes, Sherle provides the engineering clarity and confidence needed to move forward.