- End-to-End Process Development - From Concept Definition to Construction-Ready Engineering

Engineering First-of-a-Kind (FOAK) Chemical Technologies

Chemical Process Design & Engineering

At Sherle, we provide comprehensive chemical process design and new process development services for clients across specialty chemicals, pharmaceuticals, bio-psased processes, petrochemicals, polymers, and emerging sustainable technologies.

We specialize in first-of-a-kind (FOAK) and novel chemical processes, working closely with deep-tech startups, R&D teams, and innovation-driven organizations where proven reference designs do not yet exist. Whether a project begins with a block flow diagram (BFD), early laboratory data, or a conceptual idea, we transform it into a safe, scalable, and economically viable process.

Our work is grounded in fundamental process engineering, simulation-driven design, and disciplined scale-up methodology, not assumptions or recycled templates. We support the full engineering lifecycle, from concept development and Basic Engineering Package (BEP) through Detailed Engineering Design (DED). Procurement, fabrication, erection, and commissioning support are provided through trusted execution partners, ensuring continuity from design intent to real plant operation.

Sherle actively seeks out First-of-a-Kind (FOAK) chemical processes, projects where innovation moves faster than precedent and standard design rules don’t yet exist.

We Work closly with deep-tech startups, R&D teams, and technology developers to engineer novel processes that are:

- Fundamentally sound

- Safe and controllable

- Operable under real plant conditions

- Scalable beyond pilot or demonstration scale

FOAK projects demandengineering judgment, strong fundamentals, and simulation-led thinking, not copy-paste designs. This is where Sherle adds the most value.

Our Engineering Workflow

This globally aligned workflow ensures that new, innovative, and first-of-a-kind (FOAK) chemical processes are thoroughly analyzed, de-risked, optimized, and prepared for commercial implementation.

Concept → BEP → Detailed Engineering → Procurement Support → Erection Support → Commissioning Support

Phase 1 - Conceptual Development & Process Definition

Most new chemical processes, especially FOAK technologiesstart with limited information: a block diagram, early lab data, or a proposed reaction pathway. At this stage, scale-up behavior, operability challenges, and safety risks are largely unknown.

Sherle establishes early engineering clarity by rigorously evaluating:

- Feedstock properties, impurities, stability, and variability

- Product quality requirements and downstream compatibility

- Reaction feasibility, heat release, gas evolution, fouling, and runaway risks

- Mass and energy pathways, separations, recycle and purge requirements

- Early techno-economic drivers such as utilities, batch vs continuous operation, and scale sensitivity

Concept-Stage Deliverables

- Conceptual Process Flow Diagram (PFD)

- Initial Heat & Mass Balance

- Preliminary Aspen Plus / Aspen HYSYS simulation

- Technology gap and risk assessment

- Recommended path forward (pilot plant, BEP, or further validation)

Building the Technical Foundation for Scale-Up

The Basic Engineering Package (BEP) converts a concept into a structured, simulation-validated engineering design and forms the foundation for pilot plants, cost estimation, and detailed engineering.

BEP typically includes:

- Process Design Basis (PDB)

- Detailed PFDs with operating conditions

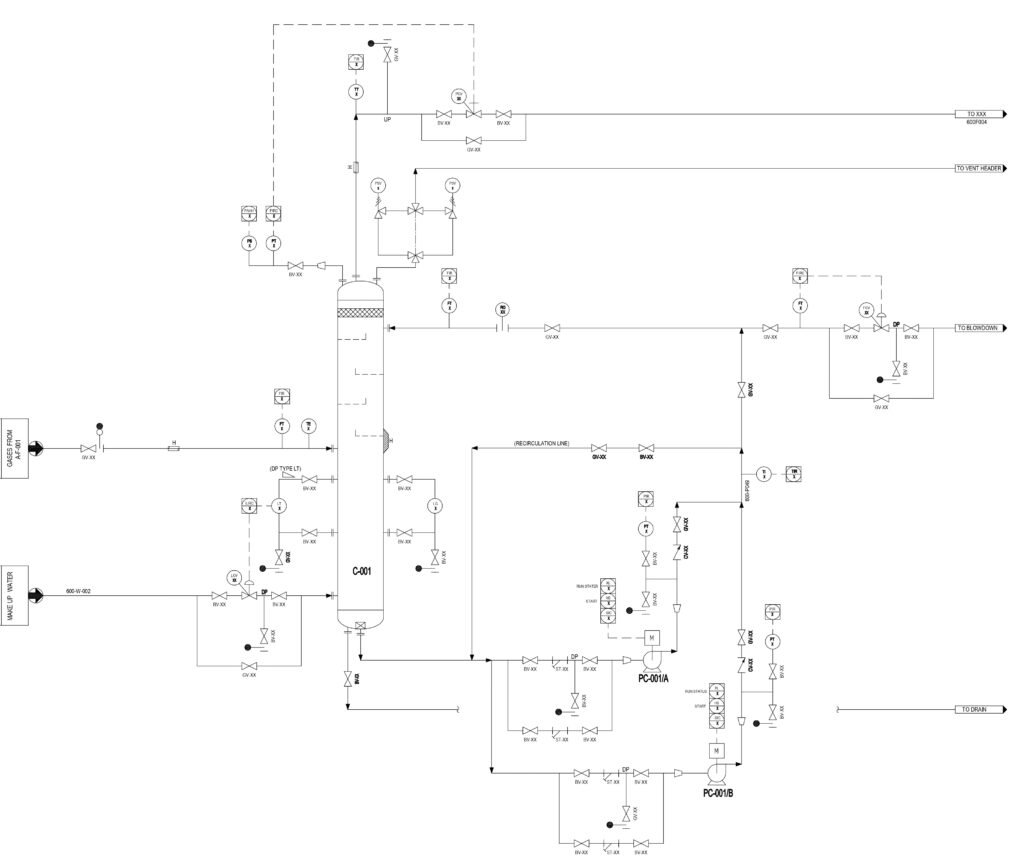

- Preliminary P&IDs defining major equipment, control philosophy, and safety intent

- Refined Aspen Plus / HYSYS simulations with validated thermodynamics

- Finalized Heat & Mass Balances

- Initial sizing of reactors, columns, exchangers, pumps, and compressors

- Preliminary utility loads, plot plan, and equipment layout concepts

- Instrumentation and electrical basis (preliminary I/O counts and load estimates)

Why BEP Is Critical for FOAK & Novel Processes

For first-of-a-kind and non-standard processes, BEP is the primary risk-reduction and decision-making stage. It defines how the process will operate at scale, highlights unknowns early, supports pilot plant design, enables early CAPEX estimation, and provides clear go/no-go decision points.

BEP is the engineering backbone of safe, reliable, and economical scale-up.

Phase 2 - Basic Engineering Package (BEP)

Phase 3 - Detailed Engineering Design (DED)

Construction-Ready Engineering

Detailed Engineering Design converts the approved BEP into Issued-For-Construction (IFC) documentation suitable for fabrication, installation, and commissioning.

DED deliverables include:

- Final P&IDs and Heat & Mass Balances

- Detailed equipment datasheets and design calculations

- Piping material specifications and isometric drawings

- Civil and structural drawings

- Electrical single-line diagrams, cable schedules, and panel GA drawings

- Instrument index, loop and hook-up drawings

- Control logic documentation and Cause & Effect matrices

- Bills of Quantities (BOQs) and Material Take-Offs (MTOs)

DED serves as the execution blueprint, eliminating ambiguity during procurement and construction.

Phase 4 — Execution Support Through Trusted Partners

While Sherle’s core delivery extends through Detailed Engineering, we remain technically involved during execution. Through trusted third-party partners, we support:

- Technical bid evaluation and vendor selection

- Vendor document and drawing review

- FAT witnessing

- Site erection and pre-commissioning support

- Commissioning, startup assistance, and operator training

This ensures the process performs safely, reliably, and as designed under real operating conditions.

Codes & Standards

Our work complies with internationally recognized standards, including API 14E, API 520/521, API 2000, ASME B31.3, ANSI/ISA 75.01, ISO 5167-2, API 610/675, and TEMA / ASME Section VIII, ensuring global acceptance and regulatory compliance.

- Industries We Serve