- Code-Compliant Mechanical Engineering for Safe, Reliable & Scalable Process Plants

Mechanical Design Engineering

Mechanical Design Engineering

Mechanical engineering is where process intent becomes safe, buildable, and long-life equipment. At Sherle, we provide comprehensive mechanical design engineering services for chemical and process plants, fully compliant with ASME, API, TEMA, and ASME B31.3 codes.

We support pilot plants, modular skids, commercial plants and plant revamps, working seamlessly across BEP, Detailed Engineering (DED), and execution support. Our designs are not only code-compliant – they are practical to fabricate, install, operate, and maintain in real plant conditions.

Designed for Real Plants

We work with:

- Startups building first-of-a-kind pilot units

- SMEs scaling production safely

- Established companies executing revamps and expansions

Our focus is always on constructability, operability, safety, and long-term reliability — not over-engineering.

Our mechanical engineering services cover:

- Pressure vessels, columns, and reactors

- Storage tanks and process equipment

- Piping systems and pipe supports

- Structural design for skids and pipe racks

- Mechanical design of heat exchangers

- Integrated mechanical design for pilot plants and modular units

All work is closely coordinated with process, piping, and E&I engineering, ensuring execution-ready designs with no downstream surprises.

What We Do

Pressure Vessel Mechanical Design (ASME Section VIII)

Sherle provides complete mechanical design, analysis, and re-rating of pressure vessels handling liquid, gas, vapor, multiphase, corrosive, and high-temperature services.

Our scope includes shell, head, and nozzle thickness calculations; internal and external pressure evaluation; MAWP/MARP determination; wind and seismic analysis; nozzle reinforcement; and support design using saddles, skirts, legs, or lugs. Transportation and lifting load cases, corrosion allowance selection, flange and gasket design, and vessel re-rating studies are also covered.

We routinely design surge drums, knockout drums, flash vessels, separators, high-pressure reactor vessels, exchanger shells, filter housings, and compressor suction drums.

We design atmospheric and low-pressure storage tanks for chemicals, solvents, petroleum products, biofuels, acids, and other process liquids.

Our capabilities include fixed-roof, cone-roof, internal and external floating-roof tanks, dome and flat-roof tanks, and API 620 low-pressure tanks. Tank design covers hydrostatic checks, wind and seismic analysis, nozzle orientation, manway sizing, foundation and bund inputs, and constructability considerations. FRP and cryogenic tanks are supported through qualified partners.

Storage Tank Design (API 650 / API 620 / IS Codes)

Mechanical Design of Columns, Absorbers & Strippers

Sherle provides mechanical design for packed and tray columns used in distillation, absorption, stripping, scrubbing, and reactive separation services.

Scope includes shell and head thickness design, flange calculations, wind and seismic analysis, thermal expansion checks, tray support ring and packing support plate design, nozzle reinforcement, and platform, ladder, and access system design. Lifting, transportation, and erection load cases are evaluated to ensure safe installation.

We design mechanical systems for reactors used in chemical synthesis, polymerization, hydrogenation, oxidation, hydrolysis, and fermentation processes.

This includes jacketed reactors (half-coil, limpet, dimple, and full-coil), agitated reactors with seal selection, high-pressure reactors, pilot-scale units, CSTRs, PFRs, and slurry reactors. Mechanical design covers ASME pressure calculations, agitator shaft and seal design, jacket and coil pressure design, thermal stress evaluation, and nozzle load checks using WRC methodologies.

Reactor Mechanical Design (Agitated & Non-Agitated)

Structural Design for Skids, Platforms & Pipe Racks

We provide structural engineering for modular skids, pilot plants, pipe racks, platforms, ladders, handrails, and equipment support frames.

Structural scope includes skid base frame design, pipe rack analysis, platform and access design, and load calculations for dead, live, wind, and seismic conditions. Lifting and transportation load cases are evaluated, and fabrication drawings are issued for execution.

Our piping mechanical engineering ensures safe, flexible, and code-compliant piping systems.

Scope includes pipe thickness calculations, piping class development, material selection, routing, stress analysis, expansion loop and joint design, pump suction and discharge piping, and nozzle load compliance with API 610 and NEMA SM23. Pipe support design includes rigid supports, springs, hangers, shoes, guides, and anchors.

Piping & Pipeline Mechanical Design (ASME B31.3 / B31.1)

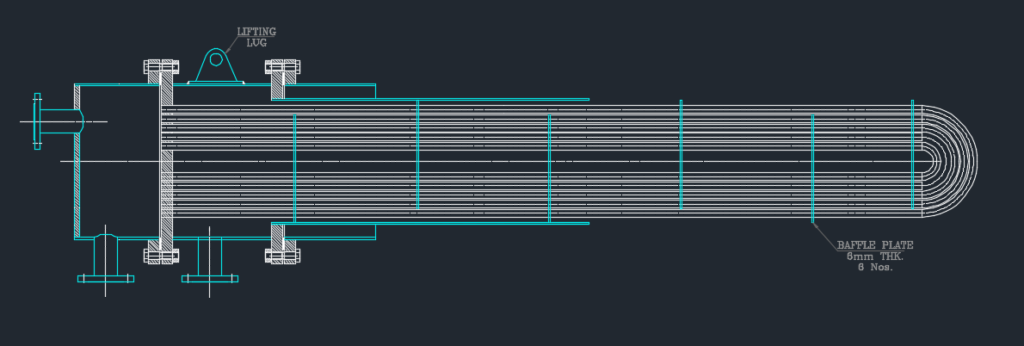

Heat Exchanger Mechanical Design (TEMA / ASME)

Complementing our thermal design services, we provide detailed mechanical design of shell-and-tube heat exchangers in accordance with TEMA and ASME Section VIII.

Scope includes tube sheet design, shell thickness calculations, baffle plate stress analysis, floating head design, gasket and flange selection, pass partition plate design, and expansion joint evaluation.

For pilot plants and modular units, Sherle delivers integrated mechanical design covering skid structures, equipment integration, piping layout and stress analysis, lifting and transportation checks, thermal expansion control, and maintenance access — critical for compact, transportable systems.

Mechanical Design for Skid-Mounted Process Systems

Mechanical Engineering Deliverables

Typical deliverables include mechanical datasheets, ASME/API/TEMA design calculations, equipment GA and nozzle orientation drawings, fabrication drawings, welding and NDT specifications, MTOs, and optional 3D models.

Mechanical Design Software

PV Elite

CAESAR II

STAAD

SolidWorks / Inventor

HTRI / Aspen EDR

- Industries We Serve Globally