- Reliable Thermal Design for Efficient, Scalable & Long-Life Operation

Heat Exchanger Thermal Design

Heat Exchanger Thermal Design

Heat exchangers sit at the heart of most chemical processes. Their performance directly affects energy efficiency, operability, safety, and long-term plant reliability. At Sherle, we provide specialized thermal and hydraulic design services for industrial heat exchangers, including reboilers, condensers, evaporators, and shell-and-tube heat exchangers.

Using industry-proven tools such as HTRI Xchanger Suite and Aspen Exchanger Design & Rating (EDR), we design exchangers that perform reliably in real plant operating conditions – not just at design point.

Our services support:

- Startups developing first-of-a-kind processes

- SMEs scaling pilot units to commercial production

- Established companies debottlenecking, revamping, or improving energy efficiency

We work across specialty chemicals, pharmaceuticals, petrochemicals, polymers, biofuels, renewable energy, oil & gas, and other process industries where thermal performance is critical.

Why Thermal Design Matters

In new and scaled-up plants, poor heat exchanger design is one of the most common causes of startup issues – leading to unstable columns, insufficient vaporization, flooding, fouling, or excessive energy consumption.

In operating plants, underperforming exchangers often become hidden bottlenecks that limit throughput or increase operating costs.

At Sherle, heat exchanger design is treated as an integrated process problem, tightly linked with process simulation, hydraulics, operability, and scale-up behavior – not just a standalone calculation.

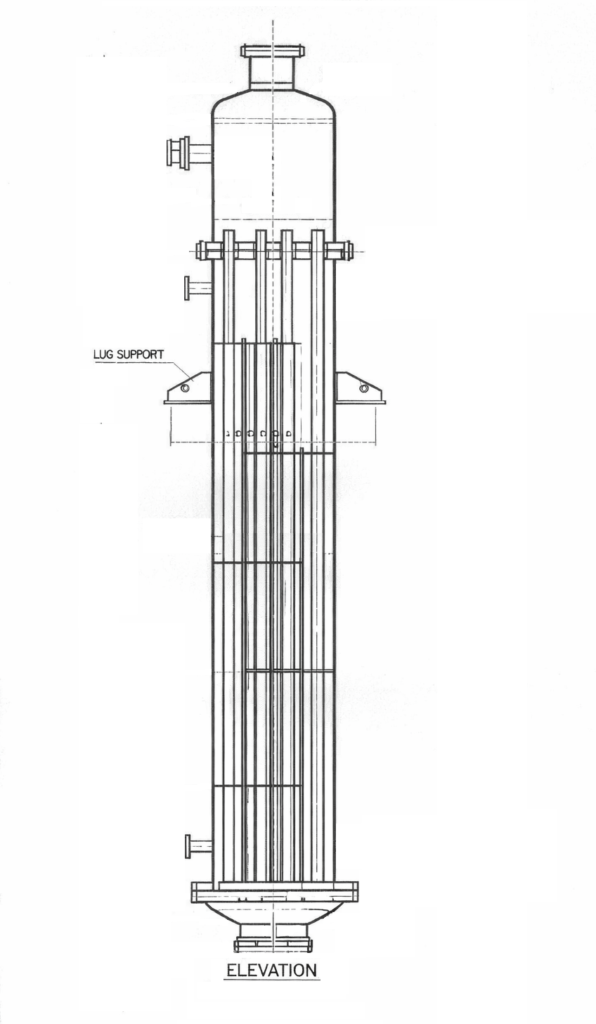

Reboiler Thermal Design & Optimization

Reboilers play a critical role in separation efficiency, column stability, and overall energy consumption. Sherle designs and optimizes all major reboiler types, selecting the appropriate configuration based on fluid properties, fouling tendency, temperature sensitivity, and required vaporization rates.

Our experience covers:

- Thermosiphon reboilers (vertical and horizontal)

- Kettle reboilers (including high vapor velocity and vacuum services)

- Falling film reboilers for temperature-sensitive systems

- Forced circulation reboilers for viscous, corrosive, or slurry services

- Special configurations such as internal column reboilers, plate and hairpin reboilers, double-pipe systems, and vapor recompression-integrated reboilers

Design considers boiling-side heat transfer, two-phase hydraulics, circulation driving force, dry-out and flooding avoidance, fouling behavior, dynamic response to load changes, and long-term operability – especially important during first-time scale-up.

Sherle designs condenser systems for distillation columns, reflux systems, vapor recovery units, vacuum services, and polymer and chemical processes.

Our experience includes:

- Shell-and-tube condensers (total, partial, reflux, subcooling, vacuum)

- Side-mounted condensers for compact column layouts

- Air-cooled condensers (forced draft, induced draft, fin-fan)

- Hammer-head condensers for high vapor loads

- Plate-type condensers for compact, low-ΔT duties

- Special condensers such as barometric, surface, falling-film, water-cooled, and brine-cooled designs

Design focuses on stable condensation across all operating cases, handling of non-condensables, pressure drop control, vapor drainage, vacuum integration, and heat recovery opportunities.

Condenser Design (All Types)

Shell-and-Tube Heat Exchanger Design (TEMA / ASME)

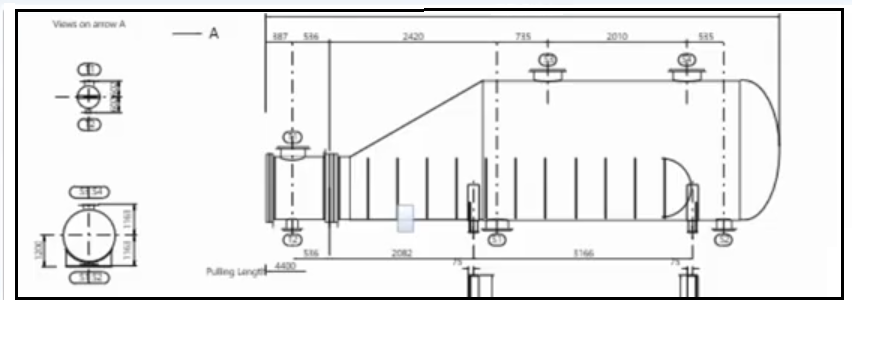

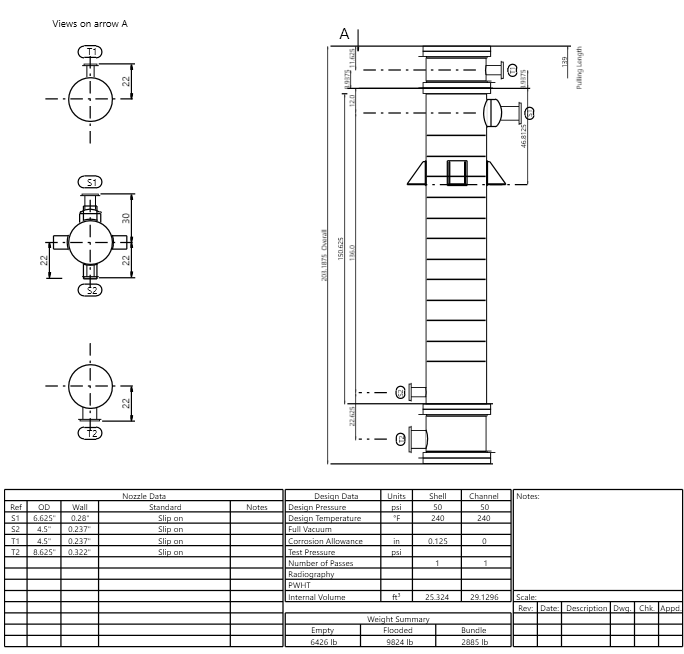

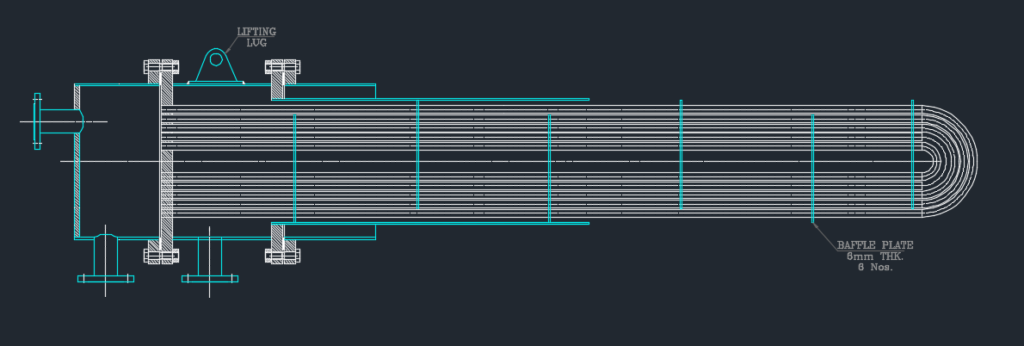

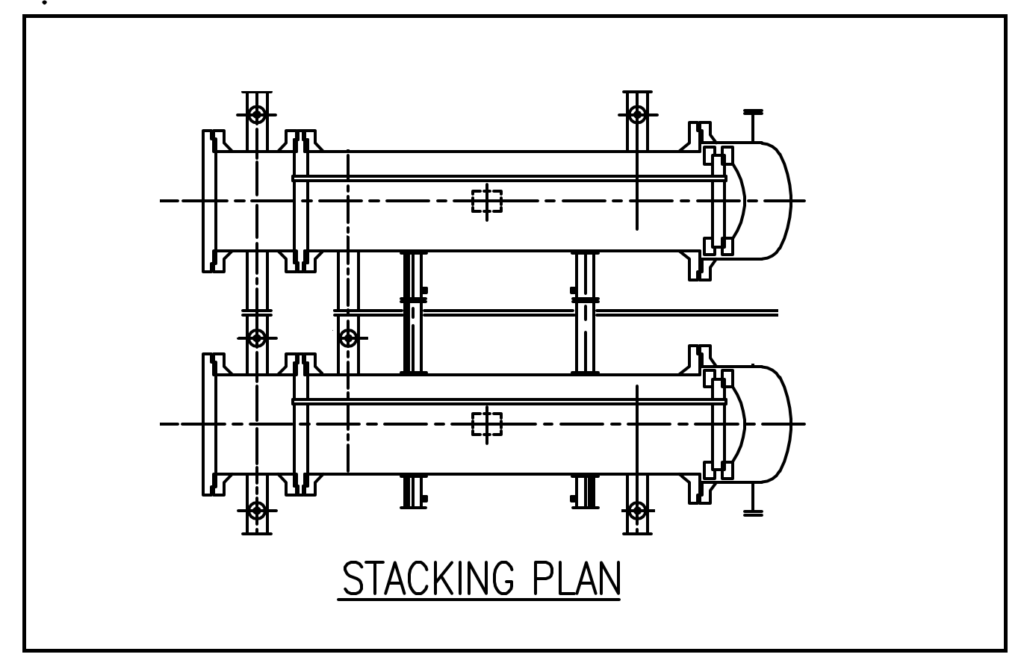

Shell-and-tube exchangers remain the workhorse of the process industry. We design exchangers for heating, cooling, condensing, vaporizing, and heat recovery in full compliance with TEMA and ASME standards.

Design covers all common shell types (E, F, G, H, J, K, X), head types (A, B, C, N, S, T), and tube configurations including multi-pass, U-tube, fixed tube sheet, and floating head designs.

Thermal sizing is supported by detailed hydraulic analysis, optimized baffle spacing, fouling factor selection, tube vibration checks, and material selection considering corrosion, erosion, temperature, and pressure limits.

We design evaporators for concentration, solvent recovery, crystallization, and separation services, where thermal behavior directly impacts product quality and operating stability.

Our experience includes falling film, forced circulation, rising film, hybrid systems, wiped film and short-path evaporators, multi-effect evaporators (MEE), and mechanical vapor recompression (MVR) systems.

Design addresses film formation, dry-out prevention, vapor-liquid separation efficiency, circulation pump sizing, fouling behavior, steam economy, and heat integration – particularly valuable for energy-intensive and sustainability-focused processes.

Evaporator & Vaporizer Thermal Design

Thermal Rating, Revamp & Troubleshooting

In addition to new designs, Sherle provides thermal rating and troubleshooting for underperforming exchangers.

We commonly address low heat duty, excessive pressure drop, fouling and scaling, tube vibration, inadequate reboiler vaporization, poor condenser performance, and hydraulic maldistribution. Using HTRI and Aspen EDR, we identify root causes and recommend practical revamp solutions such as baffle redesign, tube material upgrades, flow distribution improvements, or operating condition changes – often without full equipment replacement.

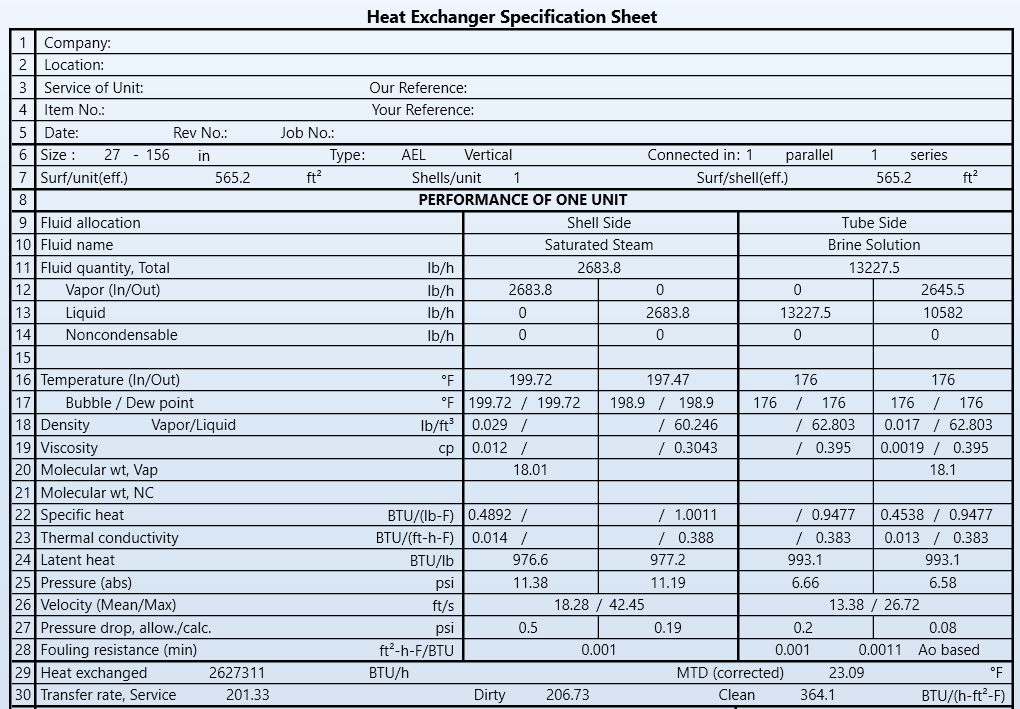

Typical deliverables include complete thermal design reports (HTRI / Aspen EDR), technical datasheets compliant with TEMA and ASME, GA drawings, hydraulic calculations, material selection guidance, and clear optimization or revamp recommendations.

Design Deliverables

Software Tools We Use

HTRI Xchanger Suite

Aspen Exchanger Design & Rating (EDR)

Pro-II / Aspen HYSYS / Aspen Plus (process integration)

- Industries We Serve Globally