- Predict. De-risk. Scale with Confidence.

Process Simulation Services

Process Simulation Services

Process simulation is a critical part of modern chemical engineering- especially when scaling technologies from laboratory concepts to pilot plants and commercial production.

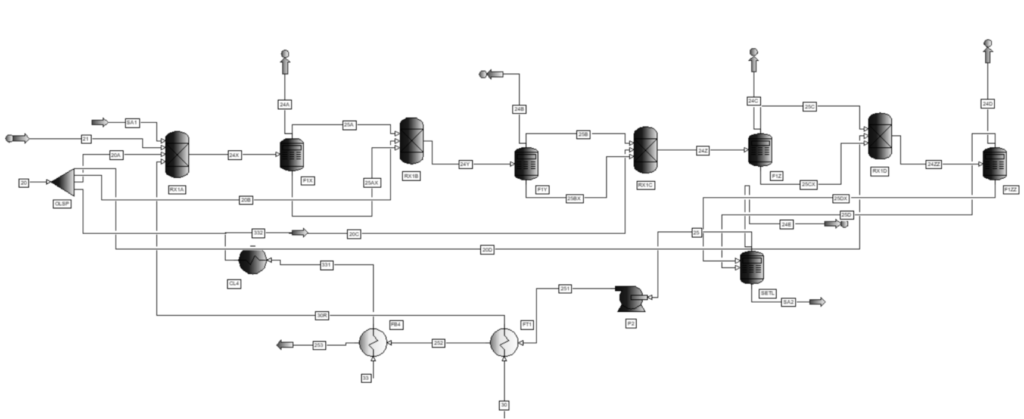

At Sherle, we use industry-standard tools such as Aspen HYSYS, Aspen Plus, Pro/II, ChemCAD, and Aspen EDR/HTRI to model, analyze, and optimize chemical processes before capital is committed. Our simulations help clients understand how a process will behave in real operating conditions-not just on paper.

We support startups, SMEs, and established chemical companies by reducing technical uncertainty early, improving process safety, optimizing energy consumption, and supporting confident scale-up decisions.

Simulation at Sherle is not treated as a software exercise. It is an engineering tool used to guide design, pilot testing, and commercial execution.

How Process Simulation Helps You

- Startups & Innovators

Validate whether a process can scale, identify risks early, and define pilot plant requirements. - SMEs & Growing Companies

Improve capacity, energy efficiency, and reliability without unnecessary capital investment. - Established Plants

Debottleneck operations, optimize performance, and support revamps or expansions.

At every stage, simulation helps convert uncertainty into engineering clarity.

Detailed Process Simulation Capabilities

Steady-State Process Simulation

We develop steady-state simulation models to describe process behavior under defined operating conditions. These models are widely used during concept development, BEP preparation, and commercial scale-up.

Steady-state simulation enables:

- Accurate heat and mass balance development

- Evaluation of unit operation performance

- Stability analysis of recycle and purge loops

- Utility consumption estimation

- Comparison of alternative process configurations

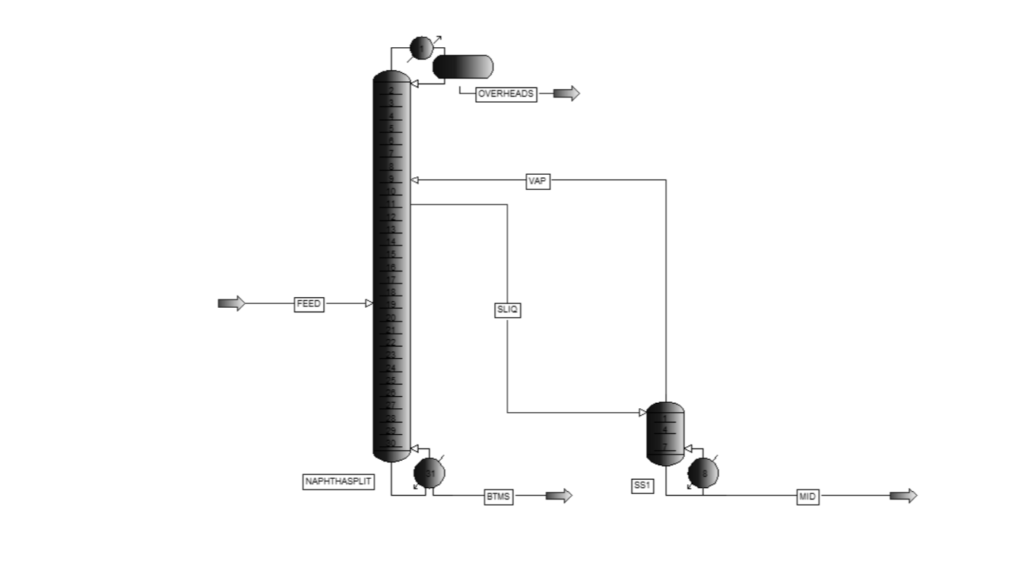

Typical applications include distillation systems, separation trains, reactors, absorbers and strippers, evaporation and crystallization systems, gas processing units, and heat exchanger networks.

Simulation plays a critical role in realistic equipment sizing, particularly for first-of-a-kind and scale-up projects.

- Distillation Columns: Binary, multicomponent, azeotropic, and extractive systems; stage count, reflux ratio, pressure profile, flooding limits, condenser and reboiler duties.

- Reactors (Batch & Continuous): Stoichiometric, equilibrium, and kinetic modeling (where data is available); conversion, selectivity, heat release, temperature control, and runaway risk evaluation.

- Separation Equipment: Absorbers, strippers, scrubbers, knockout drums, and decanters; separation efficiency and capacity analysis.

- Heat Exchangers: Simulation-driven duty estimation integrated with Aspen EDR or HTRI for reliable exchanger rating and thermal design.

Equipment Modeling & Sizing Using Simulation

Process Optimization & Debottlenecking

Simulation is a powerful tool for improving both new and operating plants. We use it to identify limitations and quantify improvement opportunities with clear technical and economic justification.

Typical studies include:

- Energy optimization and heat integration

- Column, reboiler, and condenser performance improvement

- Pump, compressor, and exchanger limitation analysis

- Yield and throughput improvement

- Solvent and recycle loop optimization

- Capacity expansion planning

This approach is especially valuable for SMEs and growing facilities, where incremental improvements can deliver significant returns.

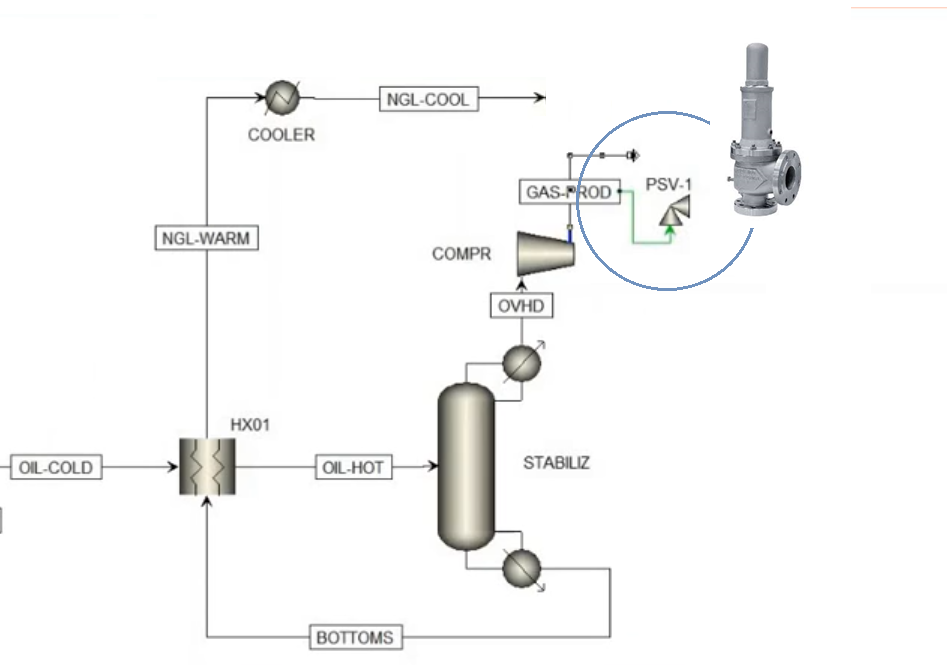

We integrate simulation closely with safety engineering to evaluate abnormal and emergency scenarios, including:

- Overpressure and relief load estimation

- Emergency depressurization analysis

- Thermal runaway assessment

- Blowdown and vent sizing

Simulation outputs are used as direct inputs for API 520/521 relief system design, DIERS-based reactor vent sizing, and safety studies—ensuring protection systems are based on realistic process behavior.

Safety Simulation & Relief System Modeling

Simulation Deliverables

Clients typically receive:

- Simulation files (Aspen HYSYS, Aspen Plus, Pro/II, ChemCAD)

- Heat and Mass Balance reports

- Stream and equipment summaries

- Equipment duty calculations

- Thermodynamic package selection and justification

- Convergence strategy documentation

- Sensitivity and optimization study results

These deliver ables are often used for internal decision-making, investor discussions, pilot planning, and smooth transition into detailed engineering.

- Industries We Serve